FAQ

QUESTION: How can I tell when my compost is done?

ANSWER: The answer to this question assumes that you have completed the first 30 days of composting (Active Phase) and are nearing the end of the second 30 days of composting (Curing).

The first indication that your compost is nearing completion is a drop in pile temperature. For small piles, the temperature will typically be well below 100oF after 60 days. However, compost is self-insulating and larger piles (say over 10 cubic yards) can maintain comparatively high temperatures, making temperature a somewhat misleading parameter.

When compost is “done”, most of the physical structure of the feedstocks will have degraded to more of a soil-like consistency. However this too can be misleading. The woody fraction in compost breaks down slowly and, therefore, you’ll see sticks, chips or shavings that are darker but have otherwise retained much of their original appearance. This is also true of horse manure balls that will have changed color throughout but retain some of their structure.

In my opinion, the most reliable way to judge whether the compost process is done is to smell it. It should have a mild, “friendly” organic fragrance. This is often referred to as a “forest-duff odor”. If your compost smells sweet (like chewing tobacco) or if it has an unpleasant sour odor (like a stale sponge), it’s not done yet. “Time heals all wounds”.

The tried and true method to evaluate compost quality is to conduct laboratory tests; however, lab tests can be pricey and the data is often difficult to interpret. For this reason I recommend using a laboratory that is familiar with testing compost. One that I often recommend is Wallace Labs in El Segundo, California. Dr. Garn Wallace provides a comprehensive compost test for about $250 and he will spend whatever time you need to understand the test results.

Lab test results are a good start to understanding the quality of a finished compost product but growth trials will tell you much more about how plants will respond to using the compost as a soil amendment (tilled into the soil) or as a mulch layer (applied to the surface).

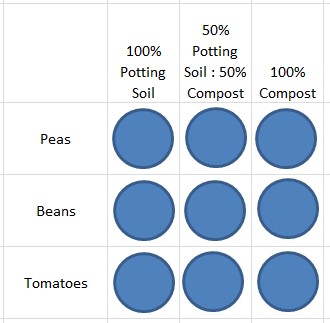

This spring, I suggest that you combine a screened sample of your compost with bagged potting soil (any brand will work). Prepare thee sets of pots (9 inch all) where three of the pots contain only the bagged potting soil; three contain the compost and potting soil at a 1:1 ratio; and three contain only screened compost. In each of the three sets of pots, plant 3 to 5 pea, bean and tomato seeds (as illustrated below).

Place the pots in a sunny location for 3 to 4 weeks and be sure to keep them watered. Take notes on how long it takes for each of the pots to germinate and how vigorously the plants grow. At the third or fourth leaf stage, pull the seedlings from the soil and compare the amount of growth above and below the soil level. With good quality compost, the 50:50 blend should outperform the others.

|