|

|

Newsletter

July 2014

|

|

|

| |

|

|

In this Issue:

* Selling Compost and Saving Chesapeake Bay

* Vermicomposting - What is it?

* Peter's Rules of Composting - Rule #3

* New System Comes Online

* Coming Events

|

Selling Compost and Helping Save Chesapeake Bay

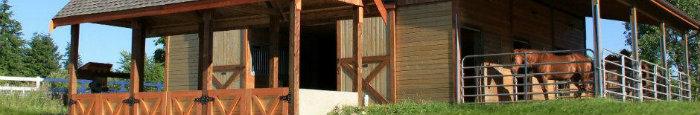

We recently heard from Jim and Mary of J&M Arabians near Smithfield, Virginia. Jim said,

|

|

|

|

"We have 16 horses ranging in age from foal to adult brood mares. Our business is breeding and raising Arabian horses. We use fine pine shavings for bedding and use a 'stall shifter' device to separate the manure from shavings, hay or other material.

Our raw product into the process is about 90-95% manure and has produced a very high quality compost, according to gardeners and landscapers who have purchased it.

|

|

We sell 30-40% of the finished product as noted, and the rest I use on my pastures, having eliminated the need to use any artificial nitrogen fertilizers and still have green grass all year.

We chose to get into the program mostly as an environmental issue. Fertilizer and chemical run off into the Chesapeake Bay is a big concern in our part of Virginia. We felt it to be our responsibility to address the manure from 16 horses more responsibly. The wood shavings are safely distributed by spreader into the surrounding woods, but since we began in 2012, not a single load of raw manure has been put on the land for possible leaching into our water system.

|

Vermicomposting - What is it?

Vermicomposting is composting with worms. Vermicompost (a.k.a. vermiculture) generally relies on the use of two species of worms: Red Wigglers (Eisenia foetida) or Red Earthworms (Lumbricus rubellus). These types of worms are rarely found in soil and are adapted to the special conditions in rotting vegetation, compost and manure piles.

Does this eliminate the need for an O2Compost system?

No. The aeration provided by an O2Compost stimulates the composting process, resulting in relatively high heat - this is referred to as the pre-composting step by Vermicomposters. This heat effectively destroys pathogens, parasites, insect larvae and weed seeds, thereby improving the finished product quality.

However, unlike normal composting, the process is interrupted between 10 and 14 days, removing some of the heat energy from the mix and leaving sufficient food value in the compost for the worms to thrive. The pre-composted manure is added to the worm bin / reactor and the worms immediately go to work.

Why go to all this effort?

There is something magical about the worm's digestive system that converts high quality compost into vastly higher quality vermicompost and worm castings. A great deal of research has been conducted at Ohio State University (and others) to test the benefits of using worm casting in potting soils. By adding 10% castings to any potting soil, it has been shown that a higher percentage of seeds will germinate and the resulting plant will grow to produce more blooms or fruit sooner, all other variables being kept equal.

Vermicompost also makes an excellent additive for brewing "Compost Tea", a topic that will be discussed in a future O2Compost Newsletter article.

Differences between Worm Castings and Vermicompost

Worm castings are the casts (manure) of a worm. It takes about a year to make 100% pure worm castings. The worms go through material many times before it becomes true castings. Vermicompost has all the benefits of castings, and more.

|

|

Is there a market for Worm Castings and Vermicompost?

Absolutely! Many O2Compost clients are vermicomposters and sell their worm castings to local organic farmers and greenhouse growers (many of them marijuana growers). One of our clients, Jack Chambers of Sonoma Valley Worm Farm, sells his worm castings for hundreds of dollars per cubic yard - no kidding.

To learn more, visit www.sonomavalleyworms.com

|

|

Peter's Rules of Composting - A 12-Part Series

Rule 3: Every question about composting has only one answer - "It Depends"

I am frequently asked questions like these:

Question: "How big does my compost system need to be?"

There are at least two answers to this question, the 'short answer' and the 'long answer'.

Short Answer: "Since you have 8 horses, I recommend you construct a 3-bin system, with each bin measuring 8-feet front to back and 4-feet high. Given that, the total footprint of the structure would be about 25-feet long and 10-feet wide."

Long Answer: "It Depends" on the number of horses that you have now and plan to have in the future. It also depends on the type of bedding that you use. If you use shavings, each bin will need to be considerably larger than if you use a wood pellet type bedding material. Do you want to store finished compost under the same roof? If so, we need to take that into account as well. Finally, many of our clients like to construct a multi-purpose building to store other items (feed, bedding materials, tractor implements, etc.).

Question: "How much will my compost system cost to construct?"

Short Answer: Somewhere between $5,000 and $15,000.

Long Answer: "It Depends" on the size of your system, the amount of site preparation, the configuration (top-down or on-grade), the types of materials you use to construct it, and who does the construction (you with help from your brother-in-law, or by an independent contractor). If you build it yourself, it will be the cost of materials and a beer. If you have a contractor build it, double your material cost and you will be in the neighborhood.

"It Depends" is, of course, tongue in cheek, but the truth is that every answer relating to composting really does depend on many factors and conditions. When people first learn about the basic composting principles, they want very specific answers (engineers are the worst - I know, I am one.)

However, most of what we know about composting is experiential and was learned through trial and error - and there have been a lot of errors. As the science and art of composting developed over many years, we have learned to rely on "truths" that generally work out to be right, but not always.

The message in all of this is two-fold. First, composters need to relax and understand that if we prepare a good mix and add oxygen, it will probably work out just fine. Second, we learn by doing, and if a batch doesn't work out exactly as we expected, it's OK to make some changes to the mix or method and try again. Besides, that's why O2Compost offers technical support. We want you to call us and ask, "What in the heck is going on with my system?"

Previous Rules:

Rule 1 - Start with the End in Mind (April Newsletter)

Rule 2 - To Learn to Compost, One Must Compost (June Newsletter) |

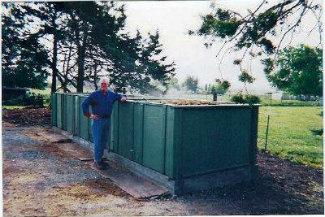

A New System Comes On-Line

|

|

|

OWNER:

John & Gayla E.

LOCATION:

Bozeman, MT

6 horses on mini wood shavings.

The finished compost is spread onto the pastures.

|

Coming Events

April 16-19, 2014

ASP Hands-On Workshop -Snohomish, Washington

This 3-day event bridges the gap between the classroom and the field.

Now taking registrations. Email sherri@o2compost.com.

For more information about how this hands-on workshop will transform your approach to composting, view our EVENT FLIER. Register soon. Space is limited to eight (8) participants.

October 26-29, 2014

AASHE Conference - Portland, Oregon

Visit their website for more information.

December 2014 (TBD)

St. John's University Compost Conference - New York City

|

|

Protecting Our Land, Air and Water Resources

|

|

O2Compost

Price-Moon Enterprises, Inc.

PO Box 1026

Snohomish, WA 98291

|

Phone: 360-568-8085

Email: info@o2compost.com

www.o2compost.com

|

|

|